Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | Spotify | iHeartRadio | RSS | More

To finish out the year strong, Lindsay and Jennifer are once again joined by Dr. Rajan Rajendran! In the previous episode, Lindsay and Jennifer discussed a lot about the new Federal Minimum Energy Efficiency standards coming in the next couple years, but what about system efficiency? Rajan dives deep into this topic and what metrics such as SEER, IEER, and EER measure, as well as what they fail to measure. We also further discuss the subject of decarbonization, the AHRI Systems Steering Committee, and why using all-electric is not always the best course of action to reduce carbon footprint.

Host: Lindsay Headings, Digital Marketing and Content Manager, Emerson

Co-host: Jennifer Butsch, Director of Regulatory Affairs, Emerson

Guest: Dr. Rajan Rajendran, Vice President of Systems Innovation Center and Sustainability, Emerson

Timestamps:

- 1:19 – Difference between today’s rated equipment efficiency and system efficiency

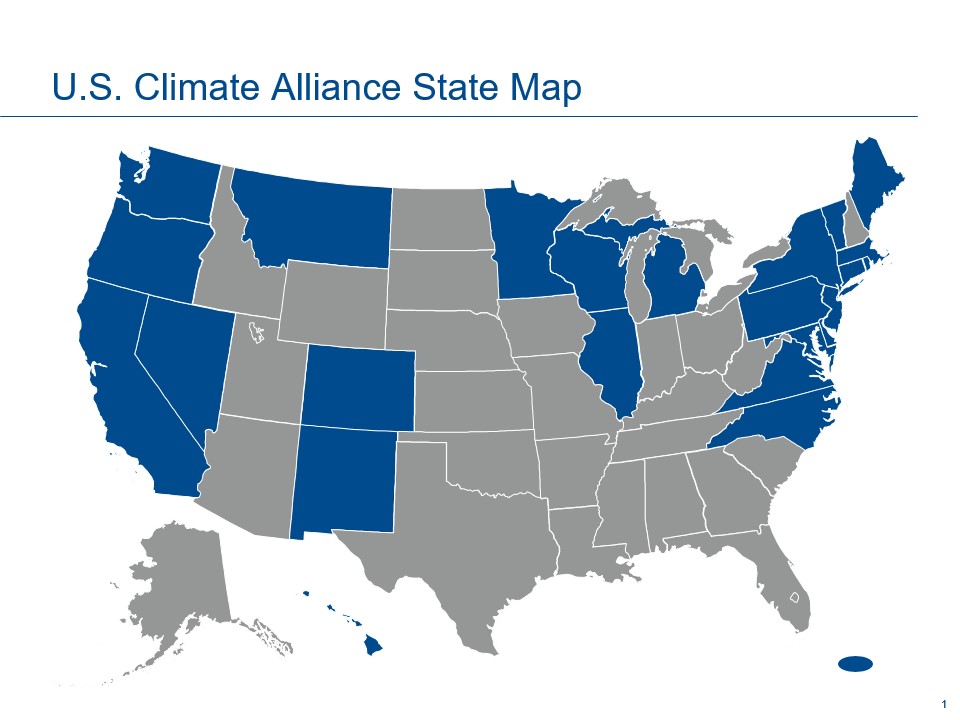

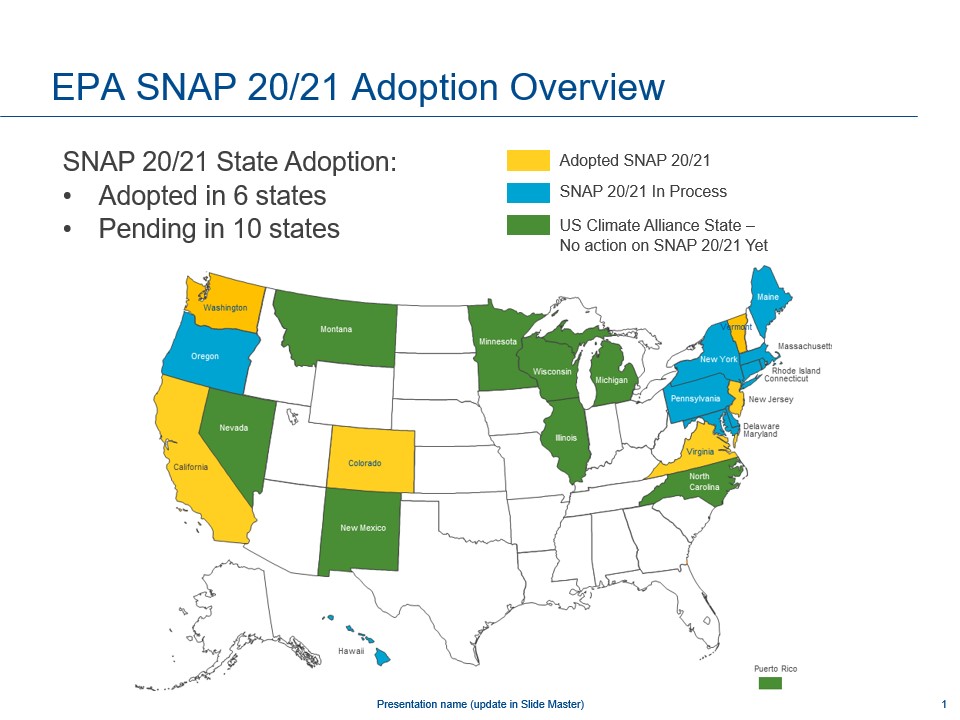

- 2:54 – Systems of equipment performance in a building or homes in USA and overseas

- 4:48 – What does decarbonization and building decarbonization mean?

- 5:59 – Main ways to reduce carbon footprint (load reduction, lower global warming refrigerant, high energy efficiency systems)

- 7:09 – Can one use an all-electric solution to decarbonize?

- 8:00 – Climate Action Plans

- 9:33 – Why build a building model?

- 11:48 – AHRI Systems Steering Committee

- Find out more about the AHRI SSC here.

- 14:21 – Will the DOE Energy Efficiency programs and today’s metrics be affected?

Previous Episode: What about efficiency? New 2023 efficiency regulations