Fresh outdoor air is required to maintain indoor air quality and a healthy building environment. However, it usually takes much more energy to treat outdoor air than recirculated air, and a large portion of this energy is spent removing humidity. Dehumidifying the air has several beneficial effects on indoor spaces:

- Decreases the latent load on cooling system

- Discourages mold and microbial growth

- Prevents condensation

- Reduces food spoilage

- Protects electronics

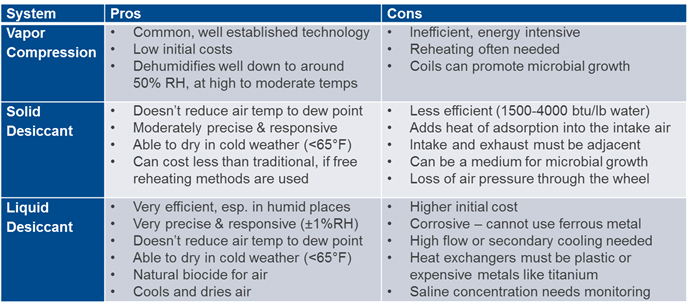

There are several methods used to dehumidify indoor air and each has its benefits and drawbacks.

Vapor Compression

A vapor compression dehumidifier uses refrigerant compression and evaporation to reduce air temperature to the dew point. A flow of air passes over the evaporation coil, cooling the air and causing condensation. The condensation is collected and the drier air is often reheated to the desired temperature.

This system relies on proven, readily available technology. It is inexpensive and easy to integrate into existing systems. However, to remove large enough amounts moisture, the air must be cooled well below comfortable levels and then reheated. There are major inefficiencies inherent in both the overcooling and reheating of supply air. Generally, the process requires much more energy below 65°F and/or 50 percent relative humidity (RH).

Solid Desiccants

Solid desiccant systems dehumidify by utilizing the water adsorbing properties of certain substances, such as molecular sieves, silica gel and activated clay. Their porous surfaces and electrostatic properties combine to attract and store moisture. Solid desiccants generally rotate between an intake and exhaust system. The desiccant captures moisture from the intake, releasing the water vapor’s heat in the process. The desiccant then rotates into the exhaust, where heated exhaust air releases the captured moisture and regenerates the desiccant.

Possessing few moving parts, solid desiccant dehumidifiers are attractive due to their simplicity, responsiveness and potential lower energy cost. If free exhaust heat is available for regeneration, there can be significant energy savings. However, using additional energy to regenerate the solid desiccant is largely inefficient. Solid desiccant systems also require intake and exhaust airflows to be adjacent, which can cause design constraints or inefficiencies.

Liquid Desiccants

Liquid desiccant systems, like their solid counterparts, use the water absorbing properties of chemical substances to dehumidify. Liquid desiccant systems expose incoming air to a concentrated saline solution, which readily absorbs moisture from the air. The resulting less-concentrated and hotter liquid is pumped to the regenerator, where additional heat desorbs the water vapor into an exhaust airflow. The re-concentrated desiccant is cooled, and then is ready to repeat the process. In order to keep from adding significant heat to the intake air as moisture is absorbed, the desiccant must either have a high flow rate or be artificially cooled.

Liquid desiccant systems are excellent for specific humidity environments, since they can dehumidify within ±1 percent RH. They can be much more efficient than vapor compression or solid desiccant systems, especially when dehumidifying below 50 percent. However, many saline liquid desiccants are very corrosive. Exposing the liquid desiccant to airflows without contamination is a concern, and usually requires a complex and more expensive system.

Dehumidification Trends

ASHRAE Standard 62.1 specifies measures regarding outdoor air to combat adverse air quality health effects. Older ventilation standards resulted in approximately 10 percent outside air by volume, but ASHRAE 62.1 now prescribes much higher requirements, which average around 30 percent outside air. To ensure occupant health, building HVAC systems will have to treat larger amounts of outdoor air.

To better combat humidity from outdoor air sources, alternative technologies and methods are being developed. A promising area of development is gas-permeable membranes. The main issue with liquid desiccant systems is the direct exposure of the desiccant to airflow, causing desiccant contamination and potential HVAC system corrosion. If a membrane could effectively block contaminants but still allow humidity transfer, this issue would be nearly eliminated. Liquid desiccant dehumidifiers would be much more commercially viable, and could potentially save thousands in annual energy costs.