Back to basics for technicians when servicing mildly flammable refrigerants

HVACR service technicians find themselves at the forefront of the refrigerant transition in AC and commercial refrigeration. As hydrofluorocarbon (HFC) refrigerants with high-global warming potential (GWP) are being phased down, mildly flammable A2L refrigerants have been identified as potential lower-GWP alternatives. But information about A2L servicing requirements is largely unknown in the U.S., which raises many questions within the technician community.

A2Ls have been approved by the Environmental Protection Agency’s (EPA) Significant New Alternatives Policy (SNAP) Rule 23 for use in residential AC applications as of June 2021. This includes commonly known R-454B and R-32, which are deemed acceptable subject to use conditions. Although the EPA has not yet approved A2Ls for use in commercial refrigeration, industry stakeholders soon expect further guidance and SNAP approvals.

In 2020, the passing of the American Innovation and Manufacturing (AIM) Act laid the groundwork for the transition to lower GWP refrigerants at the federal level. It grants the EPA the authority to phase down HFCs through supply limitations, sector-based controls and provides guidance on service requirements.

In addition, the California Air Resources Board (CARB) has proposed a 150 GWP limit for new refrigeration systems containing more than 50 pounds of refrigerant in California. If approved by CARB, this mandate would take effect in 2022 and favor the use of leading low-GWP alternatives, including A2Ls.

This regulatory activity is also dependent upon evolving U.S. safety standards and building codes. UL 60335-2-40 established requirements for the use of A2Ls in the AC sector, while UL 60335-2-89 is currently evaluating the potential use cases and charge limits of flammable refrigerants in commercial refrigeration. When finalized, UL 60335-2-89 will ultimately provide the basis of the CARB’s mandate and the EPA’s approval of A2Ls and its definitions of use conditions.

If you’re an HVACR technician, the chances of soon encountering A2Ls is very likely. It’s important to gain a better understanding of A2Ls to maximize safety and assist your customers with installation and service calls.

Thankfully, from a service perspective, the transition from existing refrigerants to A2Ls will not require a fundamental shift in the way you conduct business. However, it will require more rigorous attention to basic servicing fundamentals. Existing recommended best practices for A1 refrigerants will apply — with the addition of a few special considerations, new equipment, and A2L-rated tools.

A2L refrigerant characteristics

A2Ls are considered “mildly flammable” and consist of HFCs, hydrofluoroolefins (HFOs), and various blends of the two synthetic refrigerants. Many of the emerging lower-GWP refrigerants fall into this category and will be used to comply with emerging environmental regulations.

Our industry has already familiarized itself with the concept of flammable refrigerants. The “highly flammable” A3 (propane or R-290) has been used in self-contained refrigeration since the EPA approved it in its SNAP 20 ruling. Comparing the flammability differences between A2Ls and R-290 is important to understanding service considerations and relative safety risks. Consider the following key flammability criteria:

- Lower flammability limit (LFL) — A2Ls’ LFL is eight times higher than that of R-290. As such, it is less likely to form flammable concentrations, which allows for potentially larger charge sizes and applications.

- Minimum ignition energy (MIE) — R-290 has a very low MIE and can be more easily ignited by lower energy sources such as static electrical discharge. The MIE for A2Ls is significantly higher and requires an open flame or strong electrical energy source to sustain an ignition, making A2Ls safer to use with electrical components.

- Heat of combustion (HOC) — HOC is much lower in A2Ls than R-290, resulting in a lower severity of ignition events.

The potential for flammability makes the use of leak sensors and detection equipment a more important system consideration with A2Ls.

Otherwise, A2Ls have very similar characteristics and pressures as common A1 HFC refrigerants, such as R-410. Note that some blended refrigerants, such as R-454B, will have a degree of glide. Overall, servicing A2L equipment requires technicians to follow common refrigerant best practices, use A2L-rated equipment, and wear proper personal protective equipment (PPE).

Servicing best practices

Installation and repair

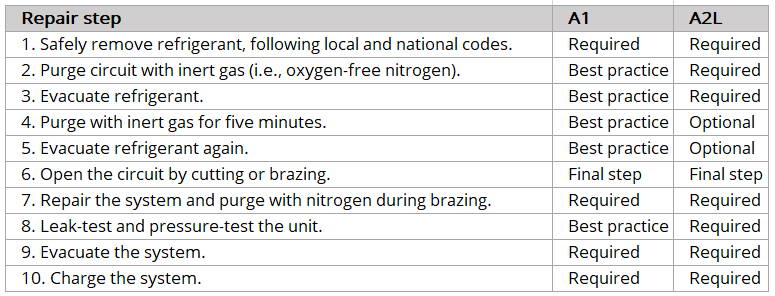

Compared to installing or repairing A1 refrigerant-based systems, A2Ls introduce three new required steps. However, these are all considered industry-accepted best practices for A1s. So for those already performing these steps, you will notice little change to your standard procedures.

Table 1: Standard repair procedures of A2L systems. Note that purging, evacuation, and leak/pressure tests will be required with A2L repairs/installations.

Table 1: Standard repair procedures of A2L systems. Note that purging, evacuation, and leak/pressure tests will be required with A2L repairs/installations.

A2L servicing tools

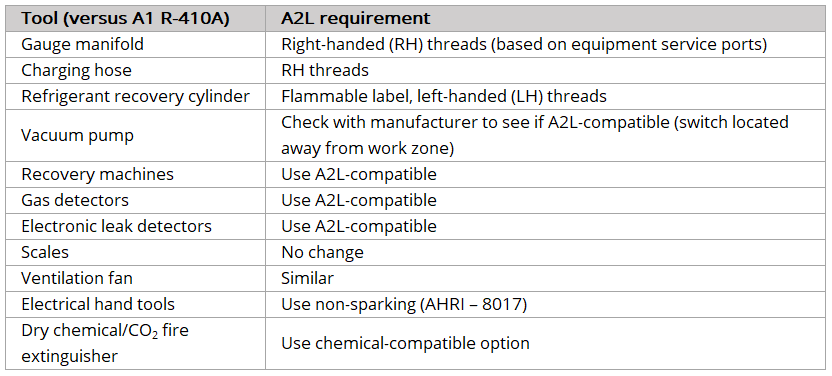

Installation and service tools are also like those used for A1s. However, it’s important to select “A2L-compatible” equipment where specified.

Table 2: Required tools for A2L systems. While similar tools will be needed to service A2L systems, be sure to use A2L-compatible equipment when applicable.

It’s important to remember that A2Ls are not a drop-in replacement for A1s in existing HFC systems; all HVACR equipment must be designed and rated to use A2Ls. While the process of charging an A2L system is similar to A1s, technicians must ensure that they do not exceed the maximum allowable charge rate.

Note: new safety labels will soon appear on A2L-based HVACR equipment to alert contractors of additional precautions. Some may also include a panel designed to cover service ports. For more information, please visit the Air-Conditioning, Heating, & Refrigeration Institute’s (AHRI) Safe Refrigerant Transition Task Force website (https://www.ahrinet.org/saferefrigerant).

A2L reclaim and recovery

Although A2L cylinders have the same rated pressure as current R-410 cylinders, tanks are designed with several distinguishing characteristics, including:

- Pressure relief valve — In the event of excessively high cylinder pressure, A2L cylinders include a pressure relief valve that’s designed to only release enough refrigerant to reduce the pressure in that cylinder. Upon release, the valve will reset.

- Red band/stripe — A2L cylinders will have a red band (stripe) or the entire top painted red to indicate the presence of the mildly flammable refrigerant.

- Left-hand (LH) thread — To further distinguish from other types of refrigerants, A2L cylinders will most likely have an LH thread.

A2L training is available

Today, industry organizations, manufacturers, and stakeholders are working together to prepare for the wider adoption of A2Ls. At Copeland, we are actively developing A2L-certified compressors, condensing units, and components to support the transition to lower-GWP refrigerants in commercial refrigeration and residential AC applications.

In addition, Copeland Education Services is developing and conducting A2L training seminars as part of our “Fit for the Future” initiative. To prepare your service team to safely install, service, and recover A2L refrigerants, please visit our course schedule.

Read Next: Client Conversations: Explaining 2023 HVAC Regulation Changes to Homeowners