Originally published on June 24, 2013

Understanding TXVs

Since the minimum efficiency regulation changed to 13 SEER in January 2006, most OEM systems now incorporate a thermostatic expansion valve (TXV) style metering device as the standard for air conditioning systems. It is now extremely important for the HVAC technician to understand the design and operation of this type of valve.

The thermostatic expansion valve (TXV) is a precision device, which is designed to regulate the rate at which liquid refrigerant flows into the evaporator. This controlled flow is necessary to maximize the efficiency of the evaporator while preventing excess liquid refrigerant from returning to the compressor (floodback).

One of the design features of the TXV is to separate the high pressure and low pressure sides of an air conditioning system. Liquid refrigerant enters the valve under high pressure via the system’s liquid line, but its pressure is reduced when the TXV limits the amount of this liquid refrigerant entering the evaporator.

Understanding the Function of the TXV

The thermostatic expansion valve controls one thing only: the rate of flow of liquid refrigerant into the evaporator. Contrary to what you may have heard, the TXV is not designed to control:

- Air Temperature

- Head Pressure

- Capacity

- Suction Pressure

- Humidity

Trying to use the TXV to control any of these system variables will lead to poor system performance – and possible compressor failure.

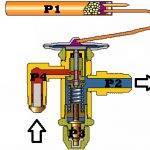

Understanding How the TXV Controls the System

As the thermostatic expansion valve regulates the rate at which liquid refrigerant flows into the evaporator, it maintains a proper supply of refrigerant by matching this flow rate against how quickly the refrigerant evaporates (boils off) in the evaporator coil. To do this, the TXV responds to two variables: the temperature of the refrigerant vapor as it leaves the evaporator (P1) and the pressure in the evaporator itself (P2). It does this by using a movable valve pin against the spring pressure (P3) to precisely control the flow of liquid refrigerant into the evaporator (P4):

TXV Pressure Balance Equation

P1+P4 = P2+P3

P1 = Bulb Pressure (Opening Force)

P2 = Evaporator Pressure (Closing Force)

P3 = Superheat Spring Pressure (Closing Force)

P4 = Liquid Pressure (Opening Force)

Understanding How the TXV Transfers Energy

Here is a closer view of the TXV in operation. The valve pin restricts the flow of the liquid refrigerant. As the flow is restricted, several things happen:

- The pressure on the liquid refrigerant drops

- A small amount of the liquid refrigerant is converted to gas, in response to the drop in pressure

- This “flash gas” represents a high degree of energy transfer, as the sensible heat of the refrigerant is converted to latent heat

- The low-pressure liquid and vapor combination moves into the evaporator, where the rest of the liquid refrigerant “boils off” into its gaseous state as it absorbs heat from its surroundings.

The pressure drop that occurs in the thermostatic expansion valve is critical to the operation of the refrigeration system. As it moves through the evaporator, the low pressure liquid and gas combination continues to vaporize, absorbing heat from the system load. In order for the system to operate properly, the TXV must precisely control the flow of liquid refrigerant, in response to system conditions.